Well Integrity- downhole inspection

Evaluation of corrosion, pitings, erosion, scale, wear and deformations, by log of multi finger calipers and magnetic thinness. Additional information can get by radial cement bond log , Acoustic Leak Flow Analyzer and Array noise tools.

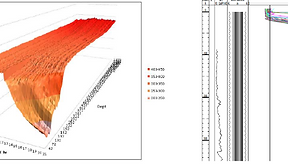

The Multi-Finger Caliper has 24 to 56 high resolution calipers which measures the internal radii of the wellbore tubing and casing. Accurate measurements can be made in tubular sizes from 1.75 inches to 9.63 inches in diameter, processing data can be display in 2D or 3D.

The Magnetic Thickness Tool is a 1-11/16 in O.D electromagnetic corrosion measuring instrument primarily run through tubing with the unique ability to simultaneously inspect tubing and the casings behind it. Latest generation tool is capable of evaluating quantitative thickness measurements up to three concentric pipes.

Radial Bond Tool using multiple receivers positioned circumferentially around the tool, provides bond data covering a sector of the casing so that a ‘ 360 deg map’ of the cement can be generated in addition to a conventional CBL log.

The array noise tool is able to measure sound produced downhole by either gas or liquid flow and detect flow around the well bore o behind the tubing or casing.

Production ( PLT) and injection (ILT ) logs

Production logging in real time or memory mode; sensors of fluid identification, flow rate (0-60,000 bpd ), pressure, temperature, capacitance array tools, gamma ray and casing collar locator - CCL. Vertical, desviated or horizontal Wells.

Injection logs (ILT) and radioactive tracers. Use of radionuclides of rapid degradation to protect the environment.

Optic Fiber- DTS

Perform permanent monitoring along the length of the well in harsh environments up to 300C (570F) in order to get the temperature profiles on depth and time to:

-

Determine the temperature losses from the surface to the area of interest.

-

Identify the sands that are being affected by the injection.

-

Determine the injection distribution in the area of interest.

Gyroscopic high resolution-continuo

High Resolution North Seeking Continuous Gyro, Depth intervals as low as 0.1 FT; high accuracy in Inclination, Azimuth, Directional analysis (casing or tubing) to detect the Micro Dogleg, Tortuosity and Maxim Diameter analysis to evaluate the best BHA placement to reduce fatigue risk and wearing.

Electric line or memory record data, not magnetic effects, high temperature.

Casing Gun - Perforating

Guns of various sizes, lengths and firing density for services of with Cable (Casing Gun) and through Pipe (Thru Tubing). Size 3 3/8” to 4 ½” , Shot density from 5 to 12 shots per foot and lengths of 4, 7, 11, 15 and 21 feet.

Borehole Seismic

The VSP refers to measurements obtained in a vertical or deviated well using geophones or fiber optic in the borehole, and a source on the surface, near the well or away from the well. In a more general context, VSPs vary in the configuration of the well, the number and position of sources and geophones, and the way in which they are deployed. Most VSPs use a seismic surface source, usually a vibrator on land and an Air gun offshore or marine environments. The VSPs include the following vertical seismic profiles:

1) Checkshot, 2) Zero offset VSP, 3) Offset VSP, 4) Walkaway VSP, 5) Deviated VSP, 6) Walkabove, 7) 3DVSP, 8) Walkaround and Crosswell seismic.

A ZVSP is a much more detailed survey than a Checkshot because geophones are more closely spaced, with a usual spacing of the order of 50 feet or less, while the former can include interval measurements with a spacing of hundreds of meters. On the other hand, a VSP uses the reflected energy contained in the trace recorded in each receiver position, in addition to the first direct path between the source and the receiver. The Checkshot uses only the travel time of the direct path. In addition to correlating the well data with the seismic data, the vertical seismic profile allows the conversion of the seismic data into zero phase data and the differentiation of the primary reflections from the multiple.